Myles Taylor’s STRUX is an active recovery orthosis for the treatment of shoulder subluxation (partial dislocation) following stroke. STRUX supports the patients shoulder while enabling and encouraging movement to promote recovery. 84% of people suffer from shoulder pain associated with subluxation after stroke. Current products are complicated, uncomfortable, unattractive and single use. Consulting healthcare professionals and stroke sufferers throughout the design process provided valuable insights that supported the refinement of concepts and prototypes.

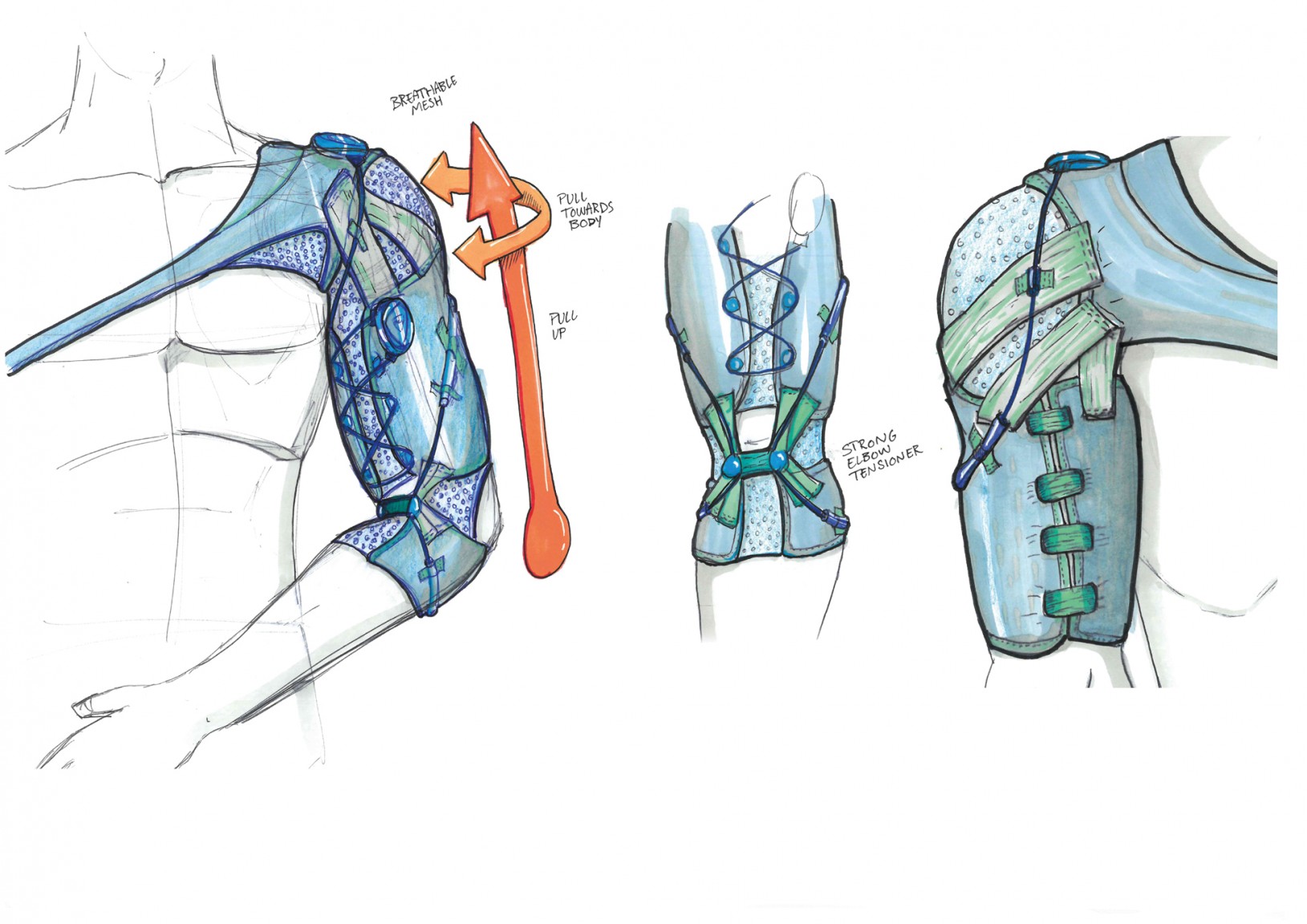

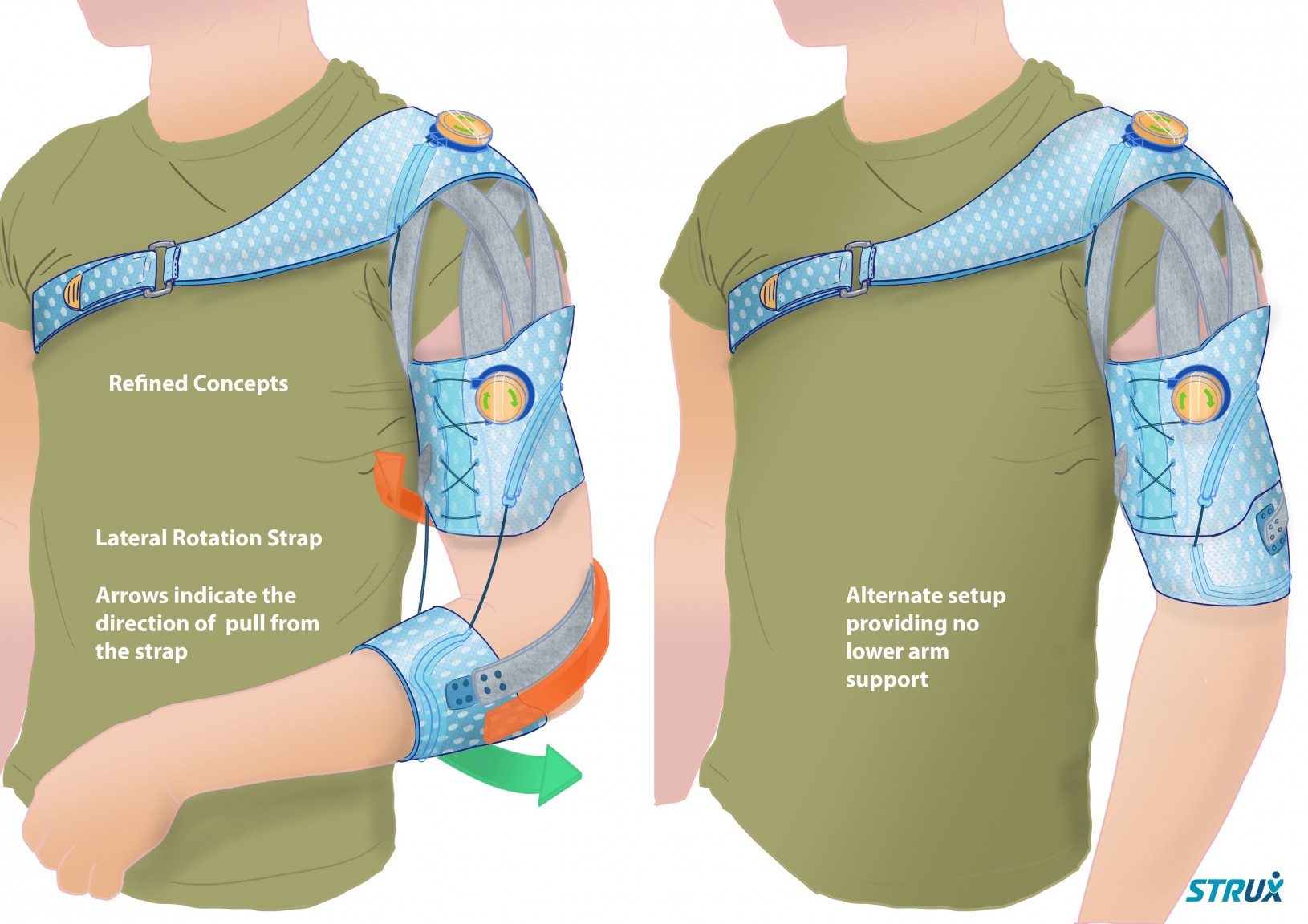

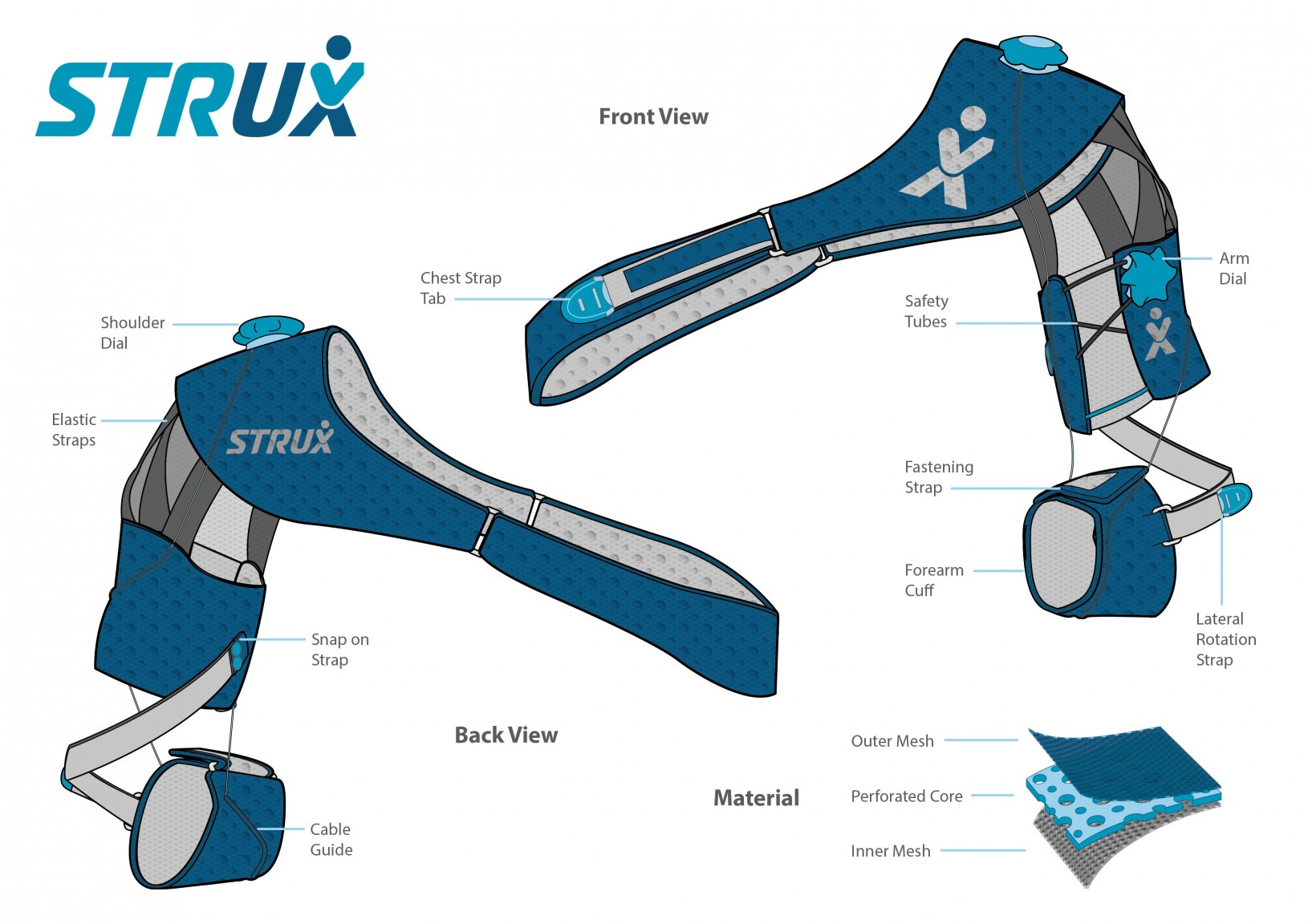

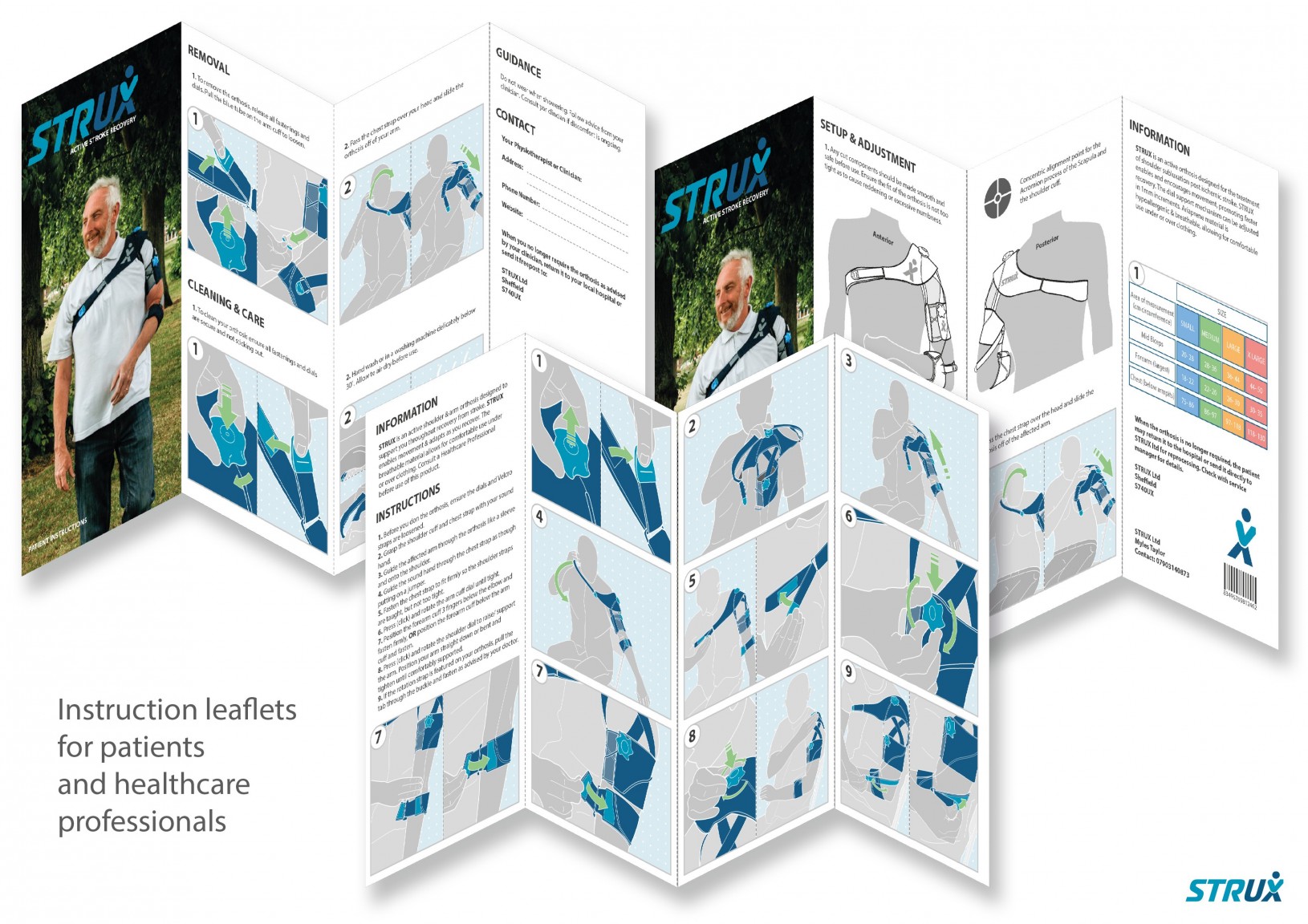

Cuffs positioned along the arm utilise fastening features in unison to support and position the arm for optimal recovery. Dial operated closure mechanisms provide precise positioning and fit when elevating the arm and securing the bicep cuff. STRUX is breathable, lightweight (145g) and hypoallergenic, providing day long comfort. Colour coded and easy to grip interaction points make adjusting features intuitive. An instructions leaflet provides additional guidance/ care information.

STRUX can be adapted and reconfigured to suit different situations and the changing requirements of a recovering patient. Patent pending features help reduce muscle spasticity, tightness and pain commonly caused by traditional orthoses. Made from 100% recyclable/ degradable material to combat the single use waste of current products. A service to reclaim and recycle used products is proposed to support sustainable manufacturing.

STRUX has received high praise from healthcare professionals and was identified as having the potential to improve people’s lives due to its versatility, intuitiveness and unique design innovations.

“The focus has been pushed towards usability. Feedback from physiotherapists has been considered. The dial closure system is superior to traditional systems for assisting with application”. – Gavin Church, Senior Physiotherapist, Community Stroke Service.

Taylor has worked with clients including Wilko and Morphy Richards.

He spent his placement year at DePuy Synthes of Johnson & Johnson, one of the largest medical device companies in the world, where he worked with global teams of bio-engineers and surgeons to design and develop devices for orthopaedic surgery. He completed theatre access training qualification, attended an orthopaedics biomechanics course and cadaver anatomy course while working at DePuy.

In his free time Taylor worked with a medical engineer to develop a functional 3D printed robotic hand intended for use at STEM events to engage kids in the disciplines of design, manufacture and electronics. Due to COVID19 restrictions, the entire functional prototype of STRUX was made by hand from scratch.

Taylor was awarded the annual student design winner from the Chartered Society of Designers. He is now studying MSc Medical Device Design at the National College of Art and Design in Dublin, Ireland.