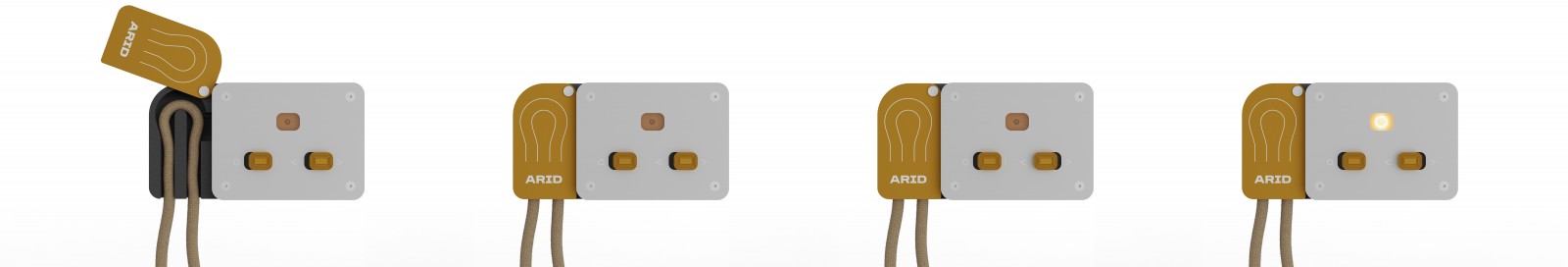

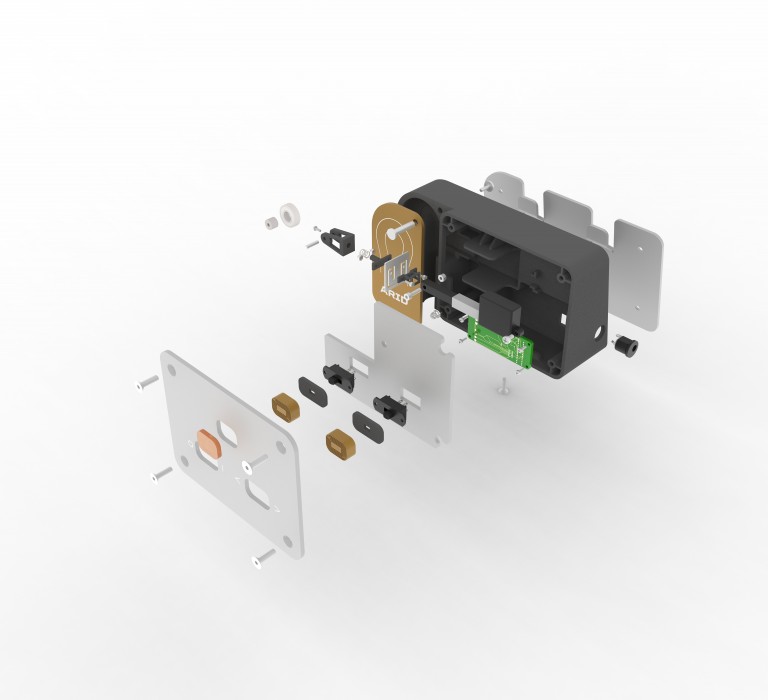

ARID (Assisted Rope Inspection Device) has been developed to improve the process of inspecting and maintaining safety critical ropes used in extreme sports, working at height, and rescue situations.

The current process for inspecting the core strength of a safety rope is long and tedious, with a person having to manually squeeze along the entire length of rope to check for irregularities or damage. This inspection process has not changed significantly since this construction of ropes began to be used in 1953.

For personal and recreational users, a survey Edward Cowan conducted on a range of climbers found that over 60% admit they do not check their safety equipment as often as they should, with rope ranking top of the list of equipment they believe they should check more. Despite this, nearly 75% of respondents believed rope to be the most important piece of equipment to inspect. When asked what deters them from checking as often as they should, most responses focused on the time and effort required for a full rope inspection.

In commercial and professional settings, climbing walls, employers and agencies adhere to set inspection procedures. Conversations with these entities revealed that they believe the current manual inspection method of ropes is too vague and time consuming, and with no quantitative data for when exactly to retire a rope a lot of decisions are made on pure opinion.

With this research, it was clear that this inspection process requires an update, to allow both recreational and professional users to check their ropes more efficiently and reliably.

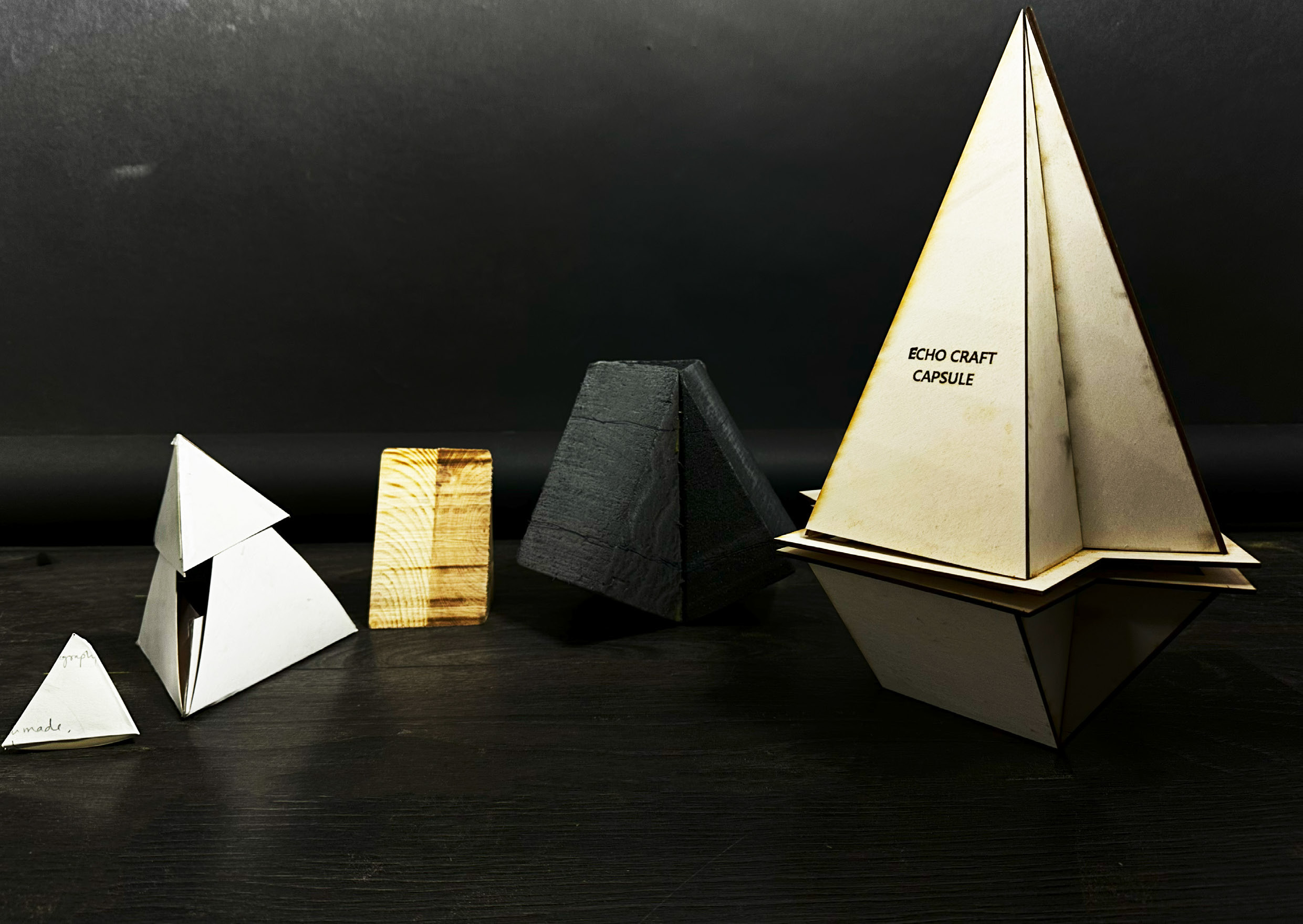

Cowan process from this point forward focused on iterative development, with quick realisation of prototypes and models to ensure the outcome was suitable for a range of environments, as well as a range of rope diameters.