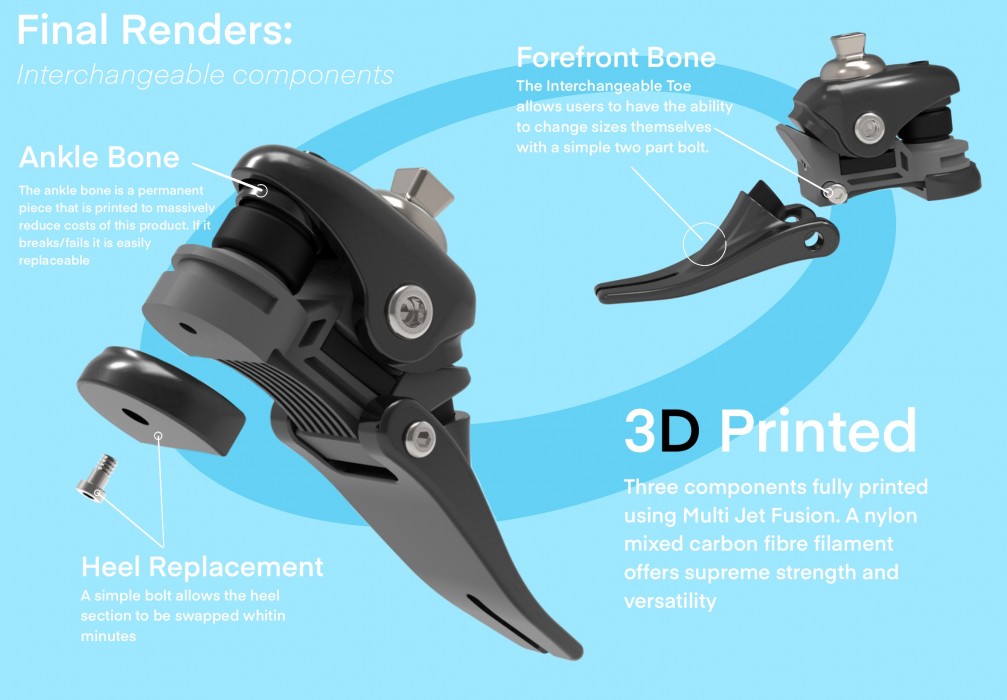

In this project the Toby Chan was tasked at creating a new prosthetic limb for children. The brief of the project was to create a new prosthetic that allows changeability and high performance whilst being affordable, with the use of modern technologies such as 3D printing. This project was a challenging new area for Chan to explore and research. Chan has always been interested in medical design and how they can create new products to improve the users’ quality of life. In this project, he wanted to make something new and exciting for existing users. The aim of this project was to tackle a known existing problem, which is that child amputees are at a massive disadvantage when it comes to existing products available to them. The average lower limb child amputee will have to be fitted with a new prosthetic limb every 6 months. This is not only extremely expensive but unsustainable making it a perfect design opportunity.

From start to finish, Chan has tried to be as efficient and resourceful as possible. With exciting interviews and interactions with leading prosthetic companies (Blatchford, Open Bionics), Chan managed to get a real hands-on experience. With exposure to existing prosthetics and products along with chatting to current market leaders, directly influencing the design and development process.

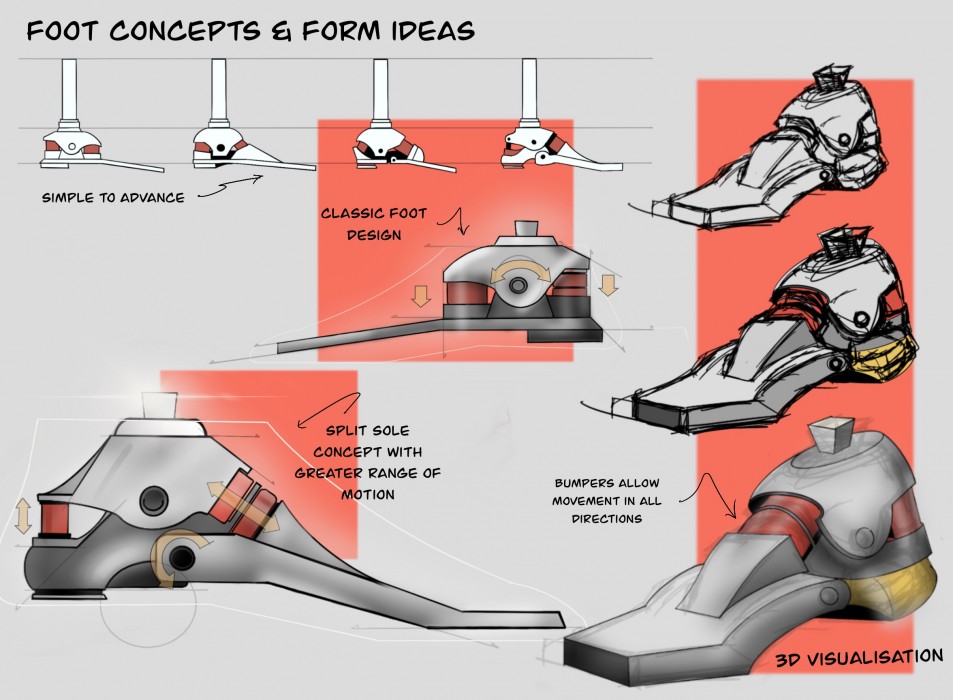

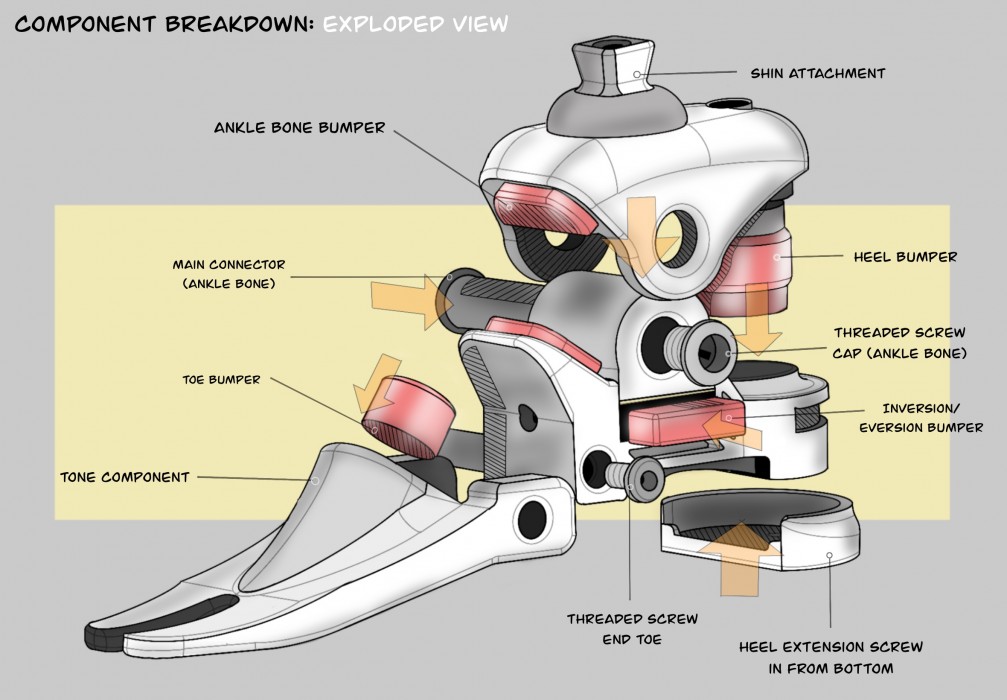

The project followed a thorough extensive design development process and testing stages to allow the product to stand up on its own in the real world. With over fifty 3D printed components made, trialled, and tested to optimise the designer’s concept, they have managed to reach what they believe to be a high level of design for their final outcome. This design not only meets user requirements but allows much more potential scope for 3D printing to be used in prosthetics in the future.